Spintric Air / Oil Separator Dry Sump

Spintric Air / Oil Separator

What is a SPINTRIC ® ?

“A totally full time functioning device, becoming part of the dry sump system.” This is not an engine breather/vent can

The "Spintric®" air/oil separator is an in-line air separator for dry sump oiling systems, as typically used on racing engines. This device follows an invention by Gary Armstrong Patented in 1983, where the air and oil is separated mechanically, being part of the dry sump pump, and incorporated within the pump, driven by the same shaft (patent # 4,414,006) 1983. The Spintric® air/oil separator is a very simple looking, yet highly sophisticated device, utilizing several complex channels allowing what I call "centripetal air separation" to work. The same laws of physics working in the previous patent, and other similar devices relying on the dry sump pump are at work. However, separators in the pump make a longer, larger diameter, more difficult to mount dry Sump pump. The Spintric® mounts separate from the dry sump pump, in-line from scavenge out to scavenge in on the dry sump tank.

The Spintric® has NO MOVING PARTS. The oil traveling back to the tank is the only "moving part". The internal centripetal (centrifugal) force is generated by the internal channels shape, cavities, port and undulated manifold, and relief ports, forces the air out of the oil prior to entering the tank. The device can be mounted virtually anywhere in the scavenge oil return line. In-line meaning that it is connected in between the scavenge outlet fitting on the pump and the return fitting on the inlet to the dry sump oil tank. There is another fitting where the extracted air that is separated from the oil scavenged out of the pan, returns to the tank. This fitting on the tank should be in a higher location, such as a vent fitting. This is important as the air extraction line is not totally without oil. The percentage of air varies with pump RPM (oil flow speed), oil temperature and flow volumes. However, the amounts generally are between 30-70% air. Keep in mind this is the same percentage of air that is NOT IN the oil as it flows into the tank. This allows the oil to be much less aerated as it makes its way to the bottom, and consequently to the pressure stage feeding the engine it's "life blood". This affords less oil pressure drop, better more efficiently cooled oil, and more lubrication to the engine. Air obviously, is not a good lubricant! I recommend the air extraction feed into the tank have a deflector, or a tube close to the internal tank wall.

Installation: The size of fittings on the Spintric® should be the same as the line size. The air outlet line should be at least a, -10 (-12 preferably). We make the units with -10, -12 or -16 in/out fittings. The Spintric® may be mounted anywhere the scavenge return line goes back to the tank, preferably, closest to the tank.

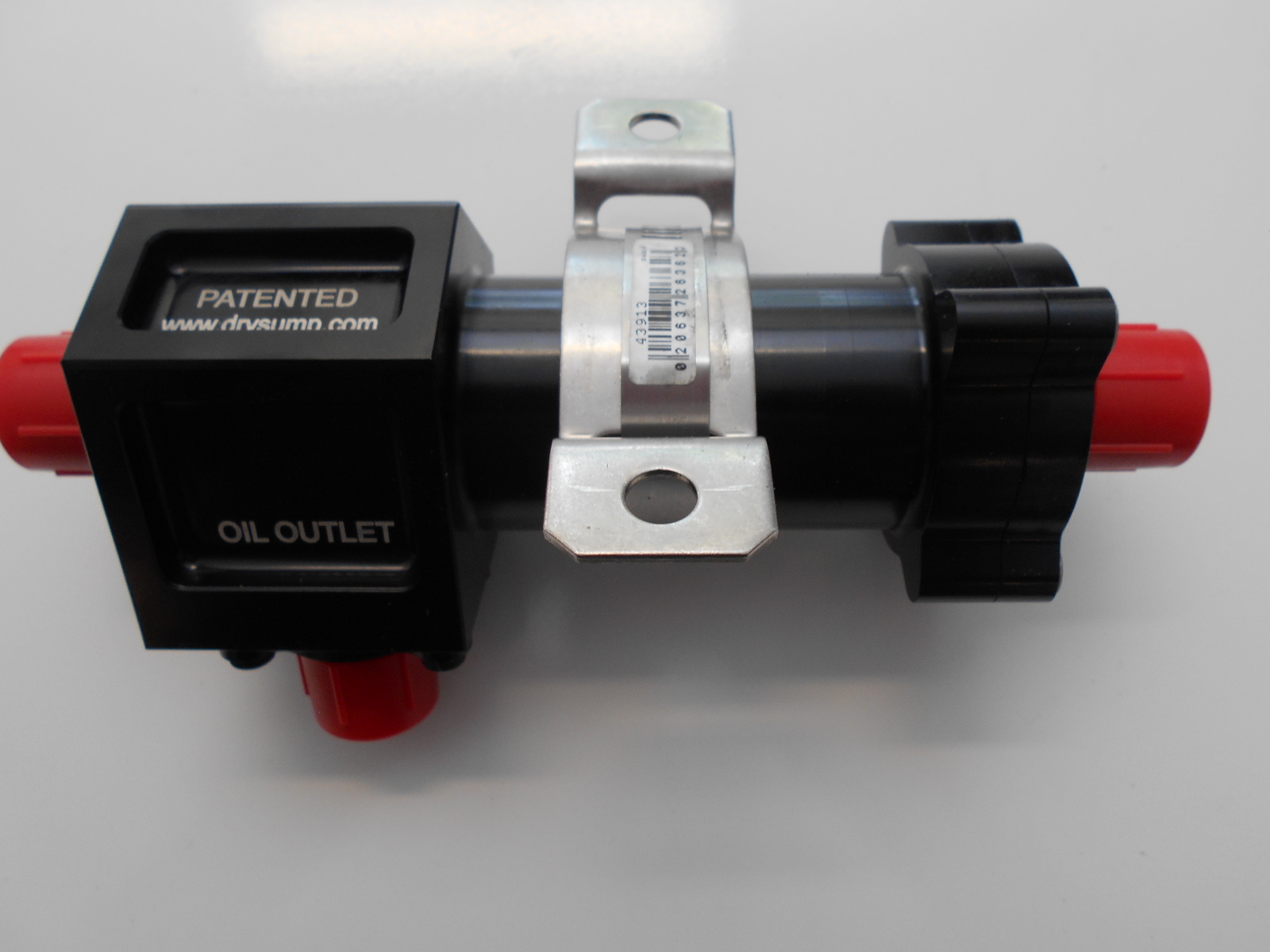

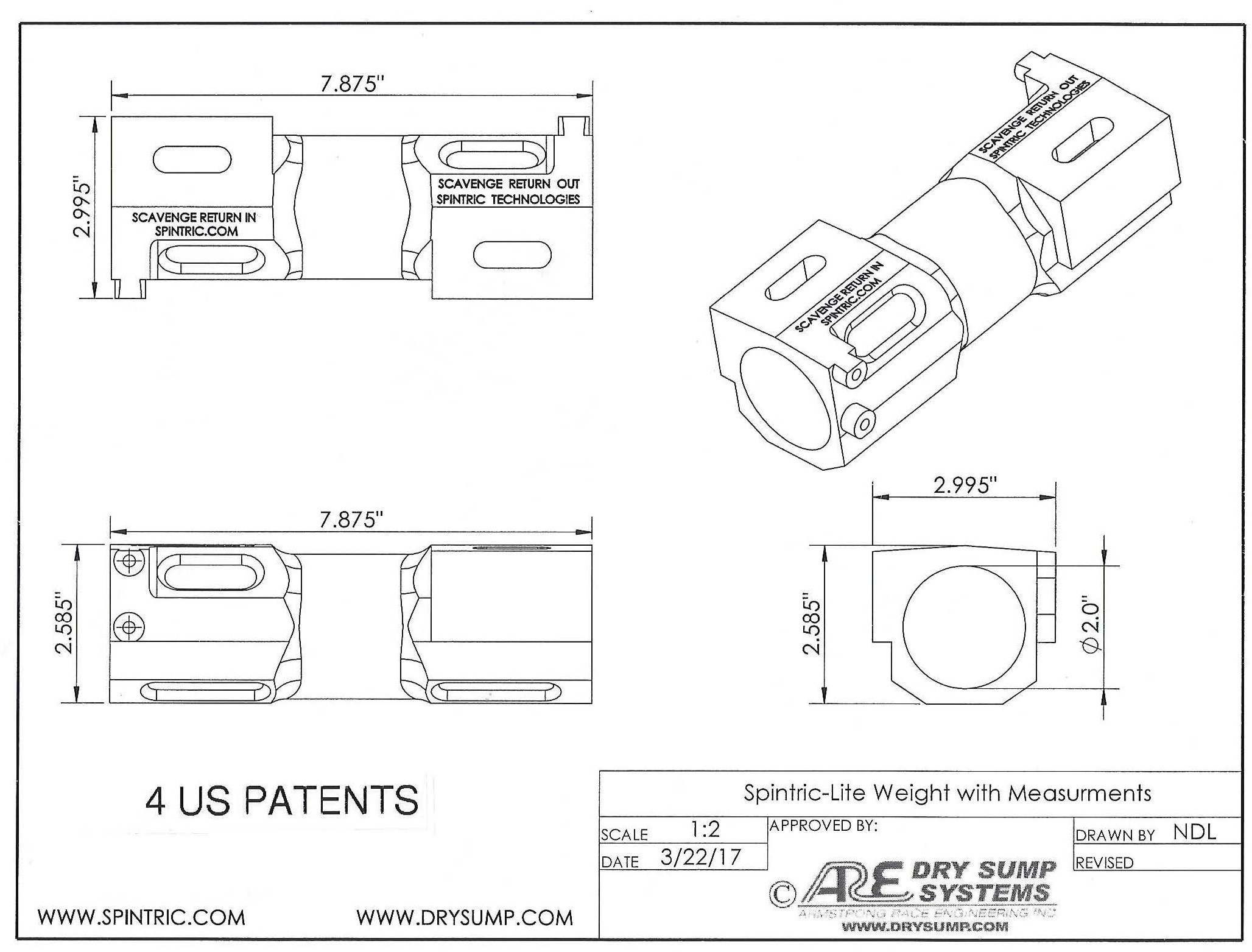

Mounting: All units come with an aircraft type stainless steel T-bolt clamp and built in bracket. This allows the unit to be securely mounted. Also, the lines to and from should be tie wrapped in position, as in standard race car plumbing procedure.

Cleaning: The Spintric® fittings and inlet and outlet manifolds are removable if necessary. However, the unit itself is permanently assembled and cannot and need not be disassembled. Units can be cleaned by running solvent, hot soapy water etc. through the entire unit, in both directions. This back flushing procedure

Part #7701 Spintric 1

Part #7702 Spintric 2

Part #7703 Spintric 3

***************************************************************

NEW Spintric® AFM

AXIAL FLOW MINI

#7700AFM

*****************************************************************

AXIAL FLOW Spintric®

#7703AF

Axial Flow Spintric mounted inside the 8" tank

Up-close look at the Axial Flow Spintric inside the 8" CNC/Cast Tank

*****************************************************************

Special Deflector Fitting for the Spintric®

Spintric® Deflector Fitting #6312-SPD

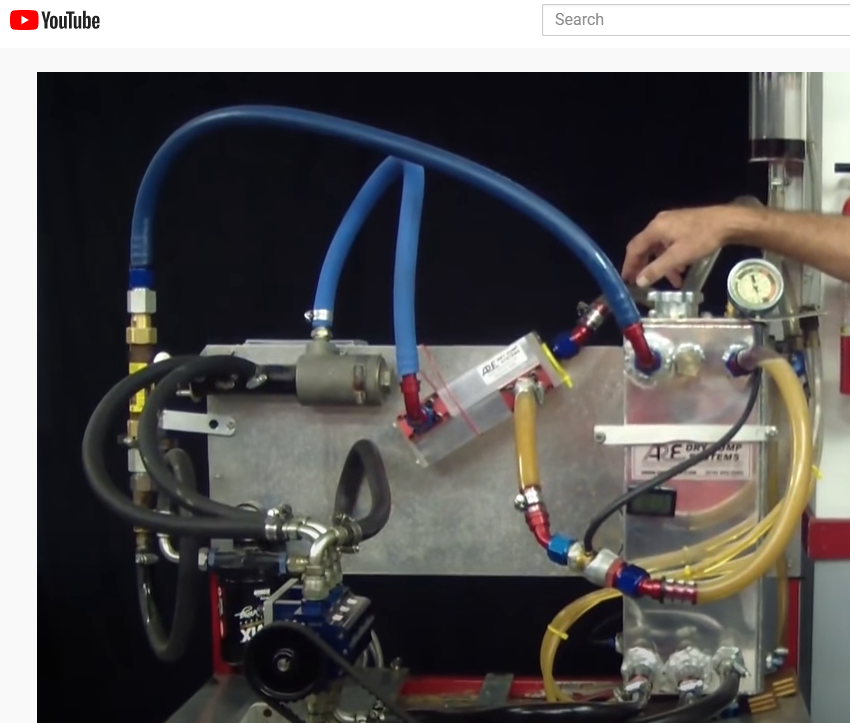

Video showing the Spintric in action

Video showing the Spintric in action

SPINTRIC® video

Example of the SPINTRIC® Air Oil Separator Flow

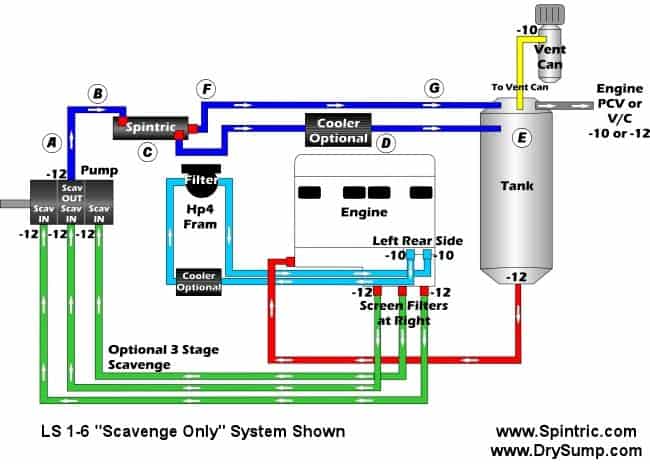

SPINTRIC® Plumbing Schematic - Incorporating the Spintric®Applies to ALL Dry Sump Systems

See Notes A through G (below)

A - DrySump Pump scavenge outlet - Return to Tank - Applies to All Pumps

B - Inlet to Spintric® - Keep Line size the same (A) through (G)

C - Outlet from Spintric® - (De-aerated oil back to tank)

D - Install Oil Cooler Here (Optional)

E - Oil Inlet to Tank - Same as before, from Pump (A)

F - Air Relief from Spintrif to Tank Top

G - Air Relief recommend through deflector fitting PN 6312

The Fluid Dynamics of the SPINTRIC®

There are literally hundreds of air/oil sparators made, a quick Google search shows that, however, 95% of them are "vented air devices" made for keeping the oil out of atmospheric or engine PCV systems. Wet sump engines need to be vented, and these devices are fine, if not a good idea.However, the SPINTRIC® is NOT in this category. The SPINTRIC® is designed to help eliminate the air from the scavenge return to the oil tank. The nature of the drysump system is to "over scavenge" the engine, sending oil and air back to the oil tank or reservoir. The SPINTRIC's® job is to send de-aerated oil back to be used again, sometimes within seconds! The air then is sent back to the top of the tank where it can be vented back to the atmosphere.

This is important to understand, as both devices separate air from oil, but in totally different dynamics, function, and end results!